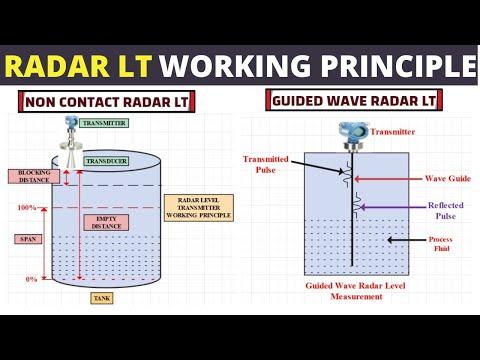

Radar Level Sensor Working Principle | Guided Wave & Non Contact Level Measurement

Guided Wave Radar (GWR) level transmitters have become increasingly popular as a dependable and accurate solution to the difficulties that industries experience with level measurement. The process of measuring the levels of liquids, slurries, and solids in various applications across diverse industries such as the oil and gas, chemical, and pharmaceutical industries has been revolutionized as a result of the development of this technology. The inner workings of GWR level transmitters, as well as their benefits and the opportunities that lie ahead for this game-changing technology, are dissected in depth in this article.

When measuring levels, GWR level transmitters apply the principles of time-domain reflectometry, also known as TDR. In order to measure the properties of the process medium, a probe, which is typically made of stainless steel, is introduced. A pulse of electromagnetic radiation with a relatively low energy level is transmitted along the probe, which is then moved through the medium. A portion of the pulse is reflected back to the transmitter whenever it comes into contact with a change in the dielectric constant, such as when GWR level transmitter comes into contact with the boundary between air and liquid. The transmitter determines the level of the medium by measuring the amount of time it takes for a pulse to travel to and from the boundary and then back again.

GWR level transmitters have a wide variety of applications and can be used to measure the levels of a variety of media, including liquids, solids, and slurries, amongst others. Additionally, they are useful in operations that involve high temperatures, high pressures, and environments that are corrosive.

Low maintenance: Because GWR level transmitters do not contain any moving parts, they require very little maintenance, which results in decreased costs and increased reliability.

By providing precise and dependable level measurements, GWR level transmitters have had a significant impact on a variety of different industries. In the future, we can anticipate further advancements in GWR level transmitters, such as improved probe materials, increased temperature and pressure tolerances, and improved integration with control systems. This is all thanks to the ongoing development of technology.

In industries such as oil and gas, chemical manufacturing, and pharmaceutical production, level measurement is an essential component of process control. There have been numerous advancements made in level measurement technology over the course of the years, but none of them have had as significant of an impact as GWR level transmitters have. In this article, we investigate the development of GWR level transmitters as well as the revolutionary impact that these devices have had on various industrial processes.

As an alternative to more conventional methods of level measurement, GWR level transmitters were initially made available on the market in the late 1990s. In order to achieve accurate and reliable level measurements, the cutting-edge technology combined the principles of radar with time-domain reflectometry, also known as TDR. Since that time, GWR level transmitters have gained widespread adoption and are now regarded as the gold standard when it comes to level measurement.